Project Aura

date: 2011 - 2015

client: Project Aura LLC

In collaboration with Jonathan Ota

It’s not your grandfather’s bicycle light, but it should be. Aura illuminates the wheels of your bicycle, increases your visual presence on the roadway and better communicates to drivers your presence and behavior. A story nearly four years in the making, what started as a side project eventually evolved into a hardware startup.

Featured on Core77, Bicycle Times, Gizmag, Make and others.

Why wheel lighting?

Immediately Identifiable

First and foremost is it imperative that drivers see and immediately recognize bicycles in the roadway at night. Typical bike lights are just individual blinking points of light, which do little to identify the bicycle as such, and are easily lost in the visual noise of the city at night.

Side visibility

Wheel lighting addresses a crucial vulnerability for cyclists. Most standard front and rear lights illuminate just that, leaving cyclists vulnerable when approached from the side. This is especially important considering that 36% of car involved bike accidents happen at intersections.

Safety is beautiful

Perhaps most important, this product is a safety product, though most people respond to it as a fashion product. Safety products are useless if they are not used, and it is almost impossible to get people excited about safety. This is the antidote.

An Intuitive Paradigm

The mission of Project Aura is to elevate the bicycle to an equal status with the automobile. But more importantly, do so in a sustainable way where cyclists are encouraged to continue using the product because it makes them feel good. Simply making a cyclist more visible is only half of the equation to make them equal with automobiles.

Cars have universally understood lighting paradigms. No matter where you are in the world, red is always a tail light, white is headlights and amber is turn signals. When you see a car at night you immediately know a lot of information about it simply because of this paradigm. However, bicycles have no such system in place, and cyclists are free to choose to illuminate or not illuminate their bikes however they want.

This poses a problem because without a lighting system drivers can anticipate, whenever they approach a cyclist they have to go through a series of cognitive steps to recognize and identify each individual bicycle. This process may take only seconds, but when traveling at 50 miles per hour, an extra few seconds to identify a bike may be the difference between tragedy and the ordinary. With Project Aura we are creating a lighting paradigm that does not need to be taught, but is intuitive. When a driver sees an Aura equipped bike at night it is impossible to mistake it for anything but a bicycle.

Dynamic Behavior

Let's look again at the automobile's lighting paradigm. It is not just a static set of lights but a dynamic interface, which broadcasts information about the vehicle's current behavior (brake lights) or intentions (turn signals). As a driver you rely heavily on knowing other vehicle's actions and intentions, why should a bicycle be any different?

Project Aura changes state based on speed, red when slow and white when at a normal riding speed. The lights immediately fade to red when deceleration is detected, acting as a brake light. The system also has an auto mode, automatically turning on when it is dark and the wheels are in motion, and turns off when the bike has been stopped for over a minute or if it is day time.

We also built a version of the product with integrated Bluetooth LTE, which allows it to communicate with a variety of web databases and APIs via your smartphone. Imagine if your lights got brighter or flashed when you were passing dangerous streets or intersections, or during inclement weather. We also worked on a concept of networking bikes near each other, so if you were riding in a group with friends, all of your lights would blink at the same rate, visually unifying you as a group.

Product Development

January - May 2011

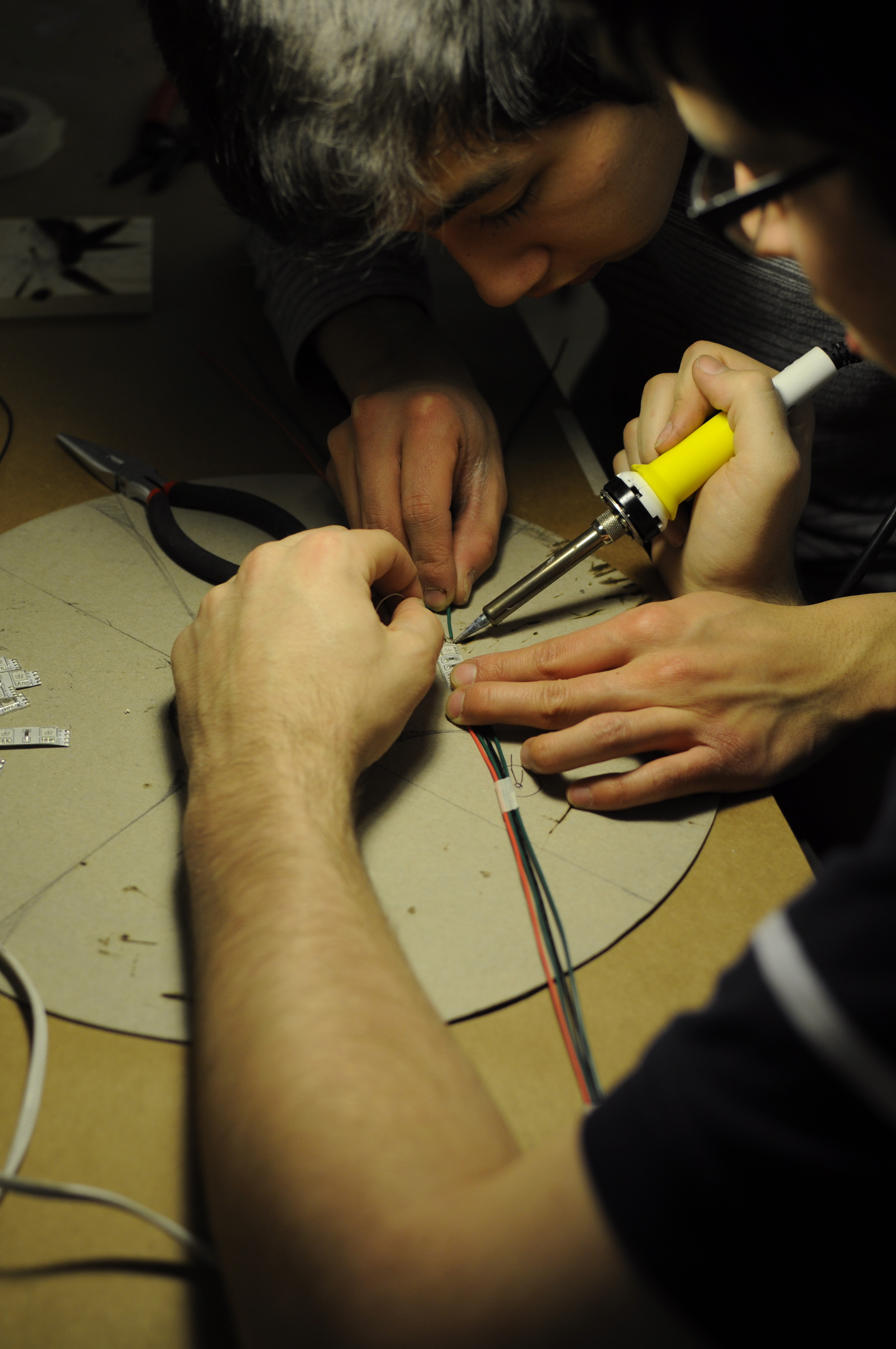

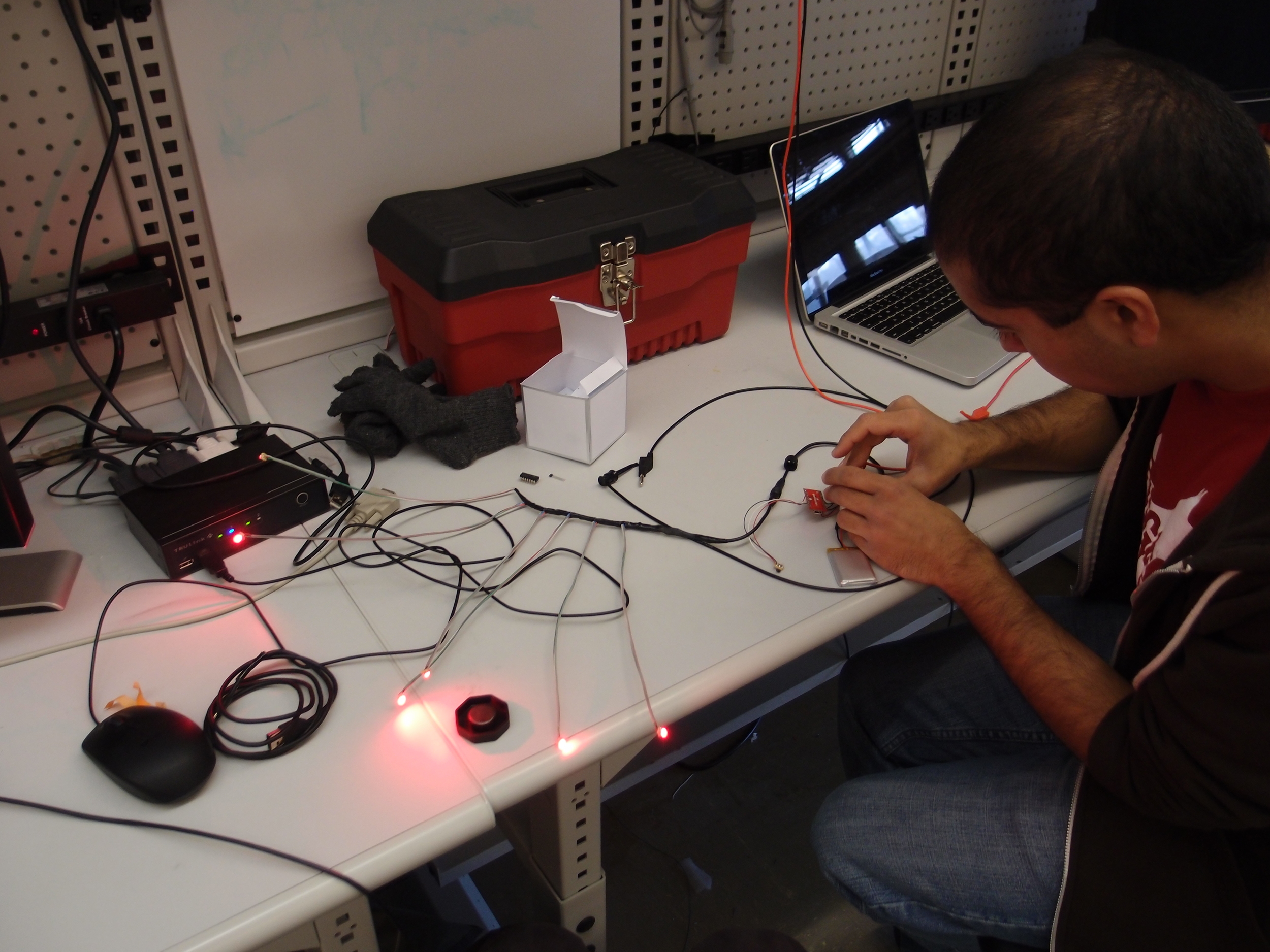

The project started as a conversation between me and Jonathan about the gaps in bicycle lighting products. We eventually buckled down and applied for a SURG (small undergraduate research grant) from Carnegie Mellon and started hacking together our idea on how to light up a bike wheel.

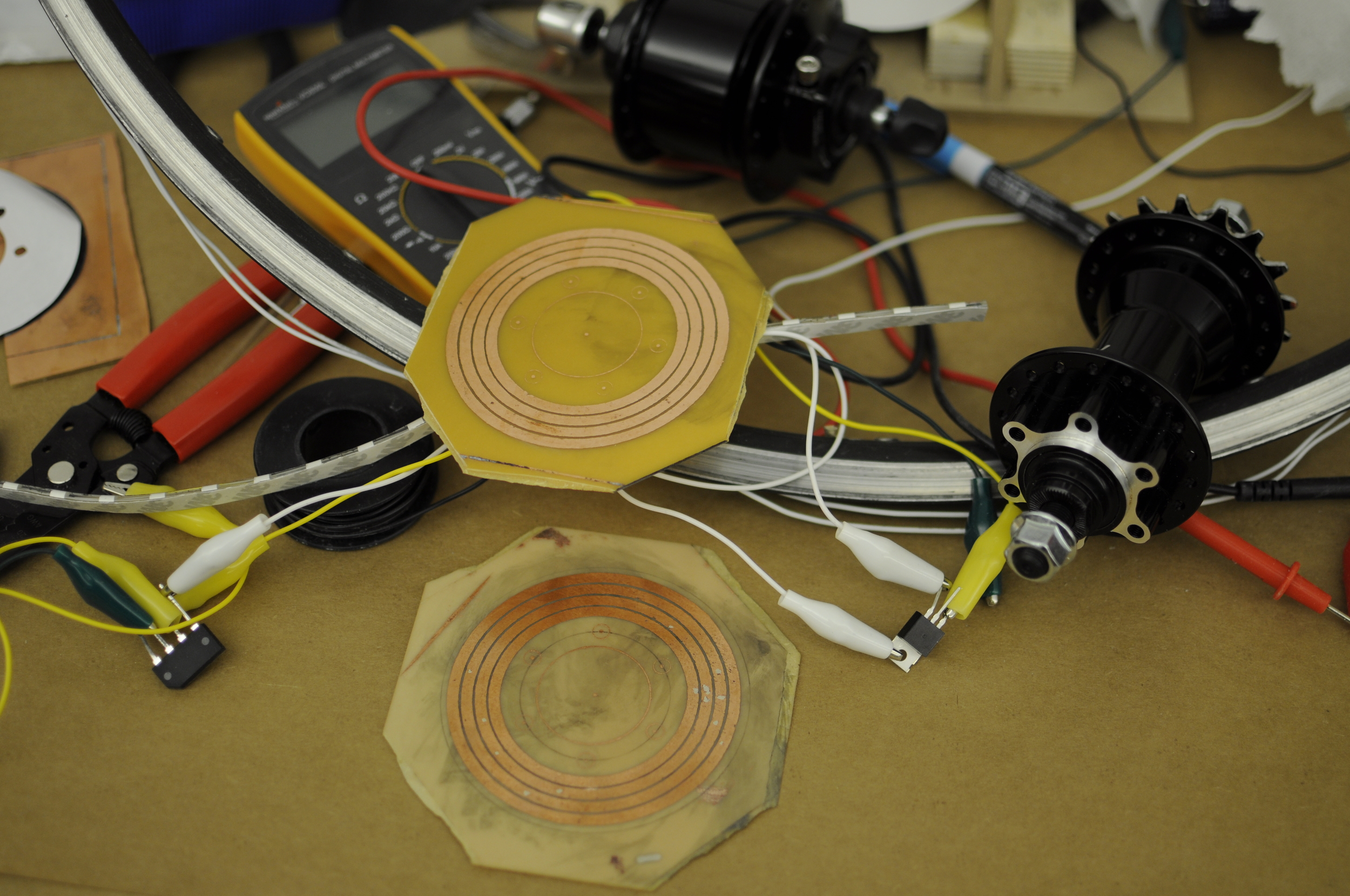

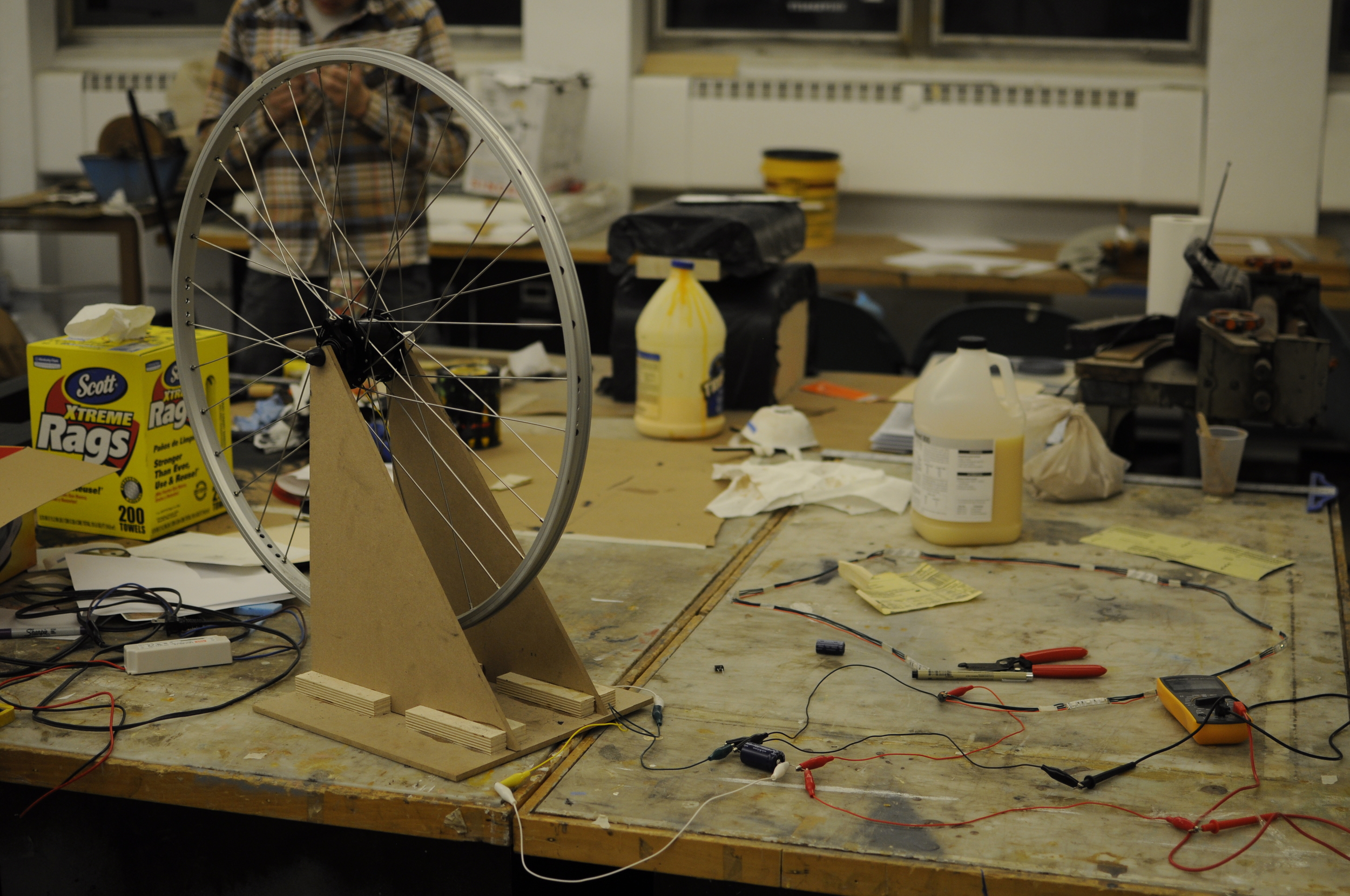

This prototype was interesting because it was powered by movement of the bike via a hub dynamo in the front wheel. There were no batteries and not even an on/off switch. When you rode, the lights lit up. This also meant that the lighting system and the bike were one and the same. The LEDs were embedded in the rims, and the wiring run on the frame. Power was taken from the front wheel, put through the power management bundle and then routed to each moving wheel through custom sliprings we made ourselves.

By the end of the semester we had finished the prototype, put together a snazzy video and went off to enjoy the summer. Somebody saw the video and submitted it to Core77, who then wrote an article about the project. The post went viral and soon there were sites all over the internet writing about the project, and the video racked up over 100,000 views in a week. People started asking where they could buy it. The only problem was it was only a one off prototype. We soon realized we had something real on our hands and started planning a second prototype while we were both studying abroad in the Netherlands. Living among the Dutch really changed my perception about the role of the bicycle and still influences me today.

September 2011 - August 2012

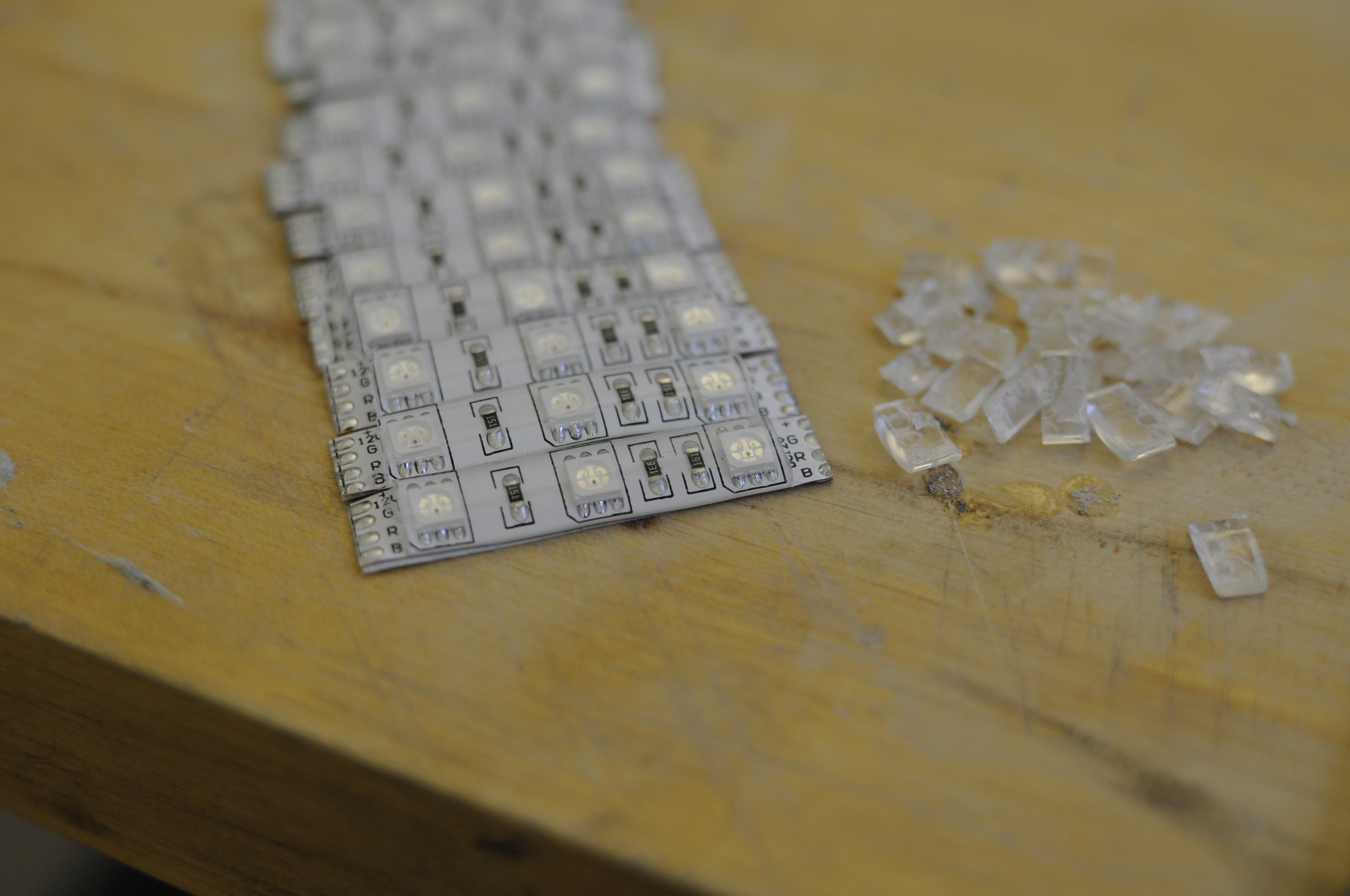

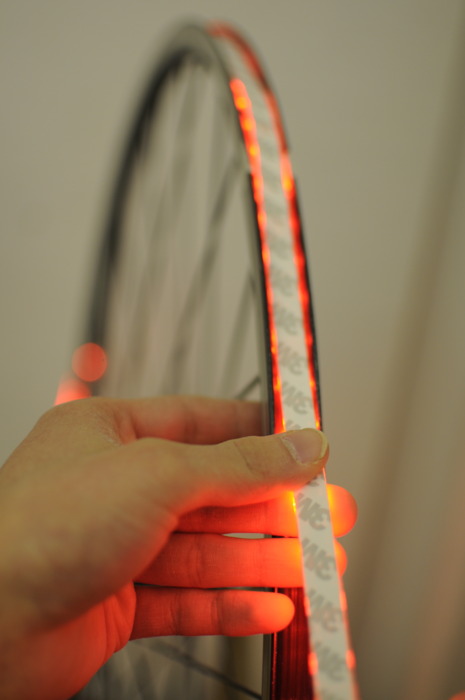

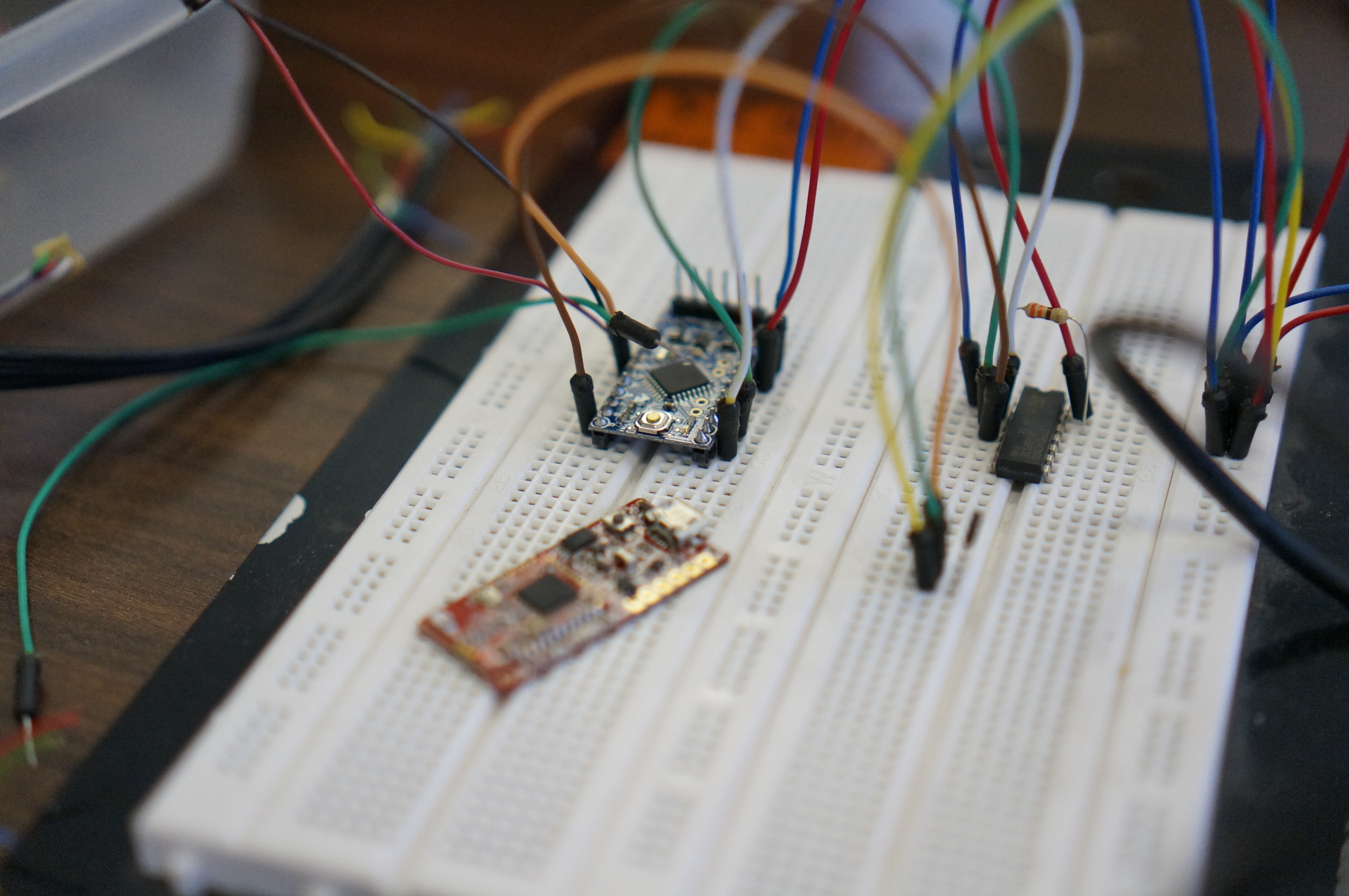

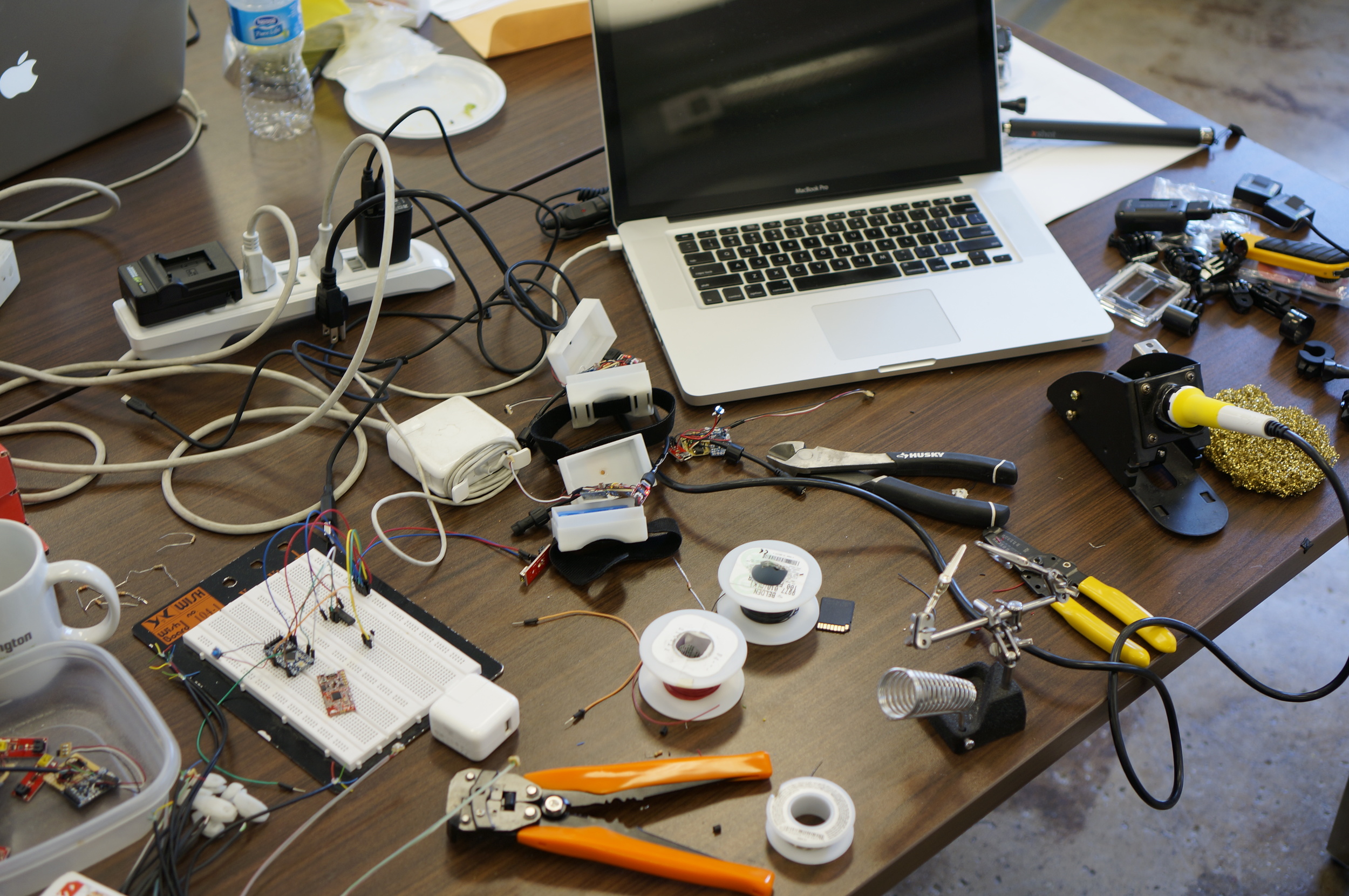

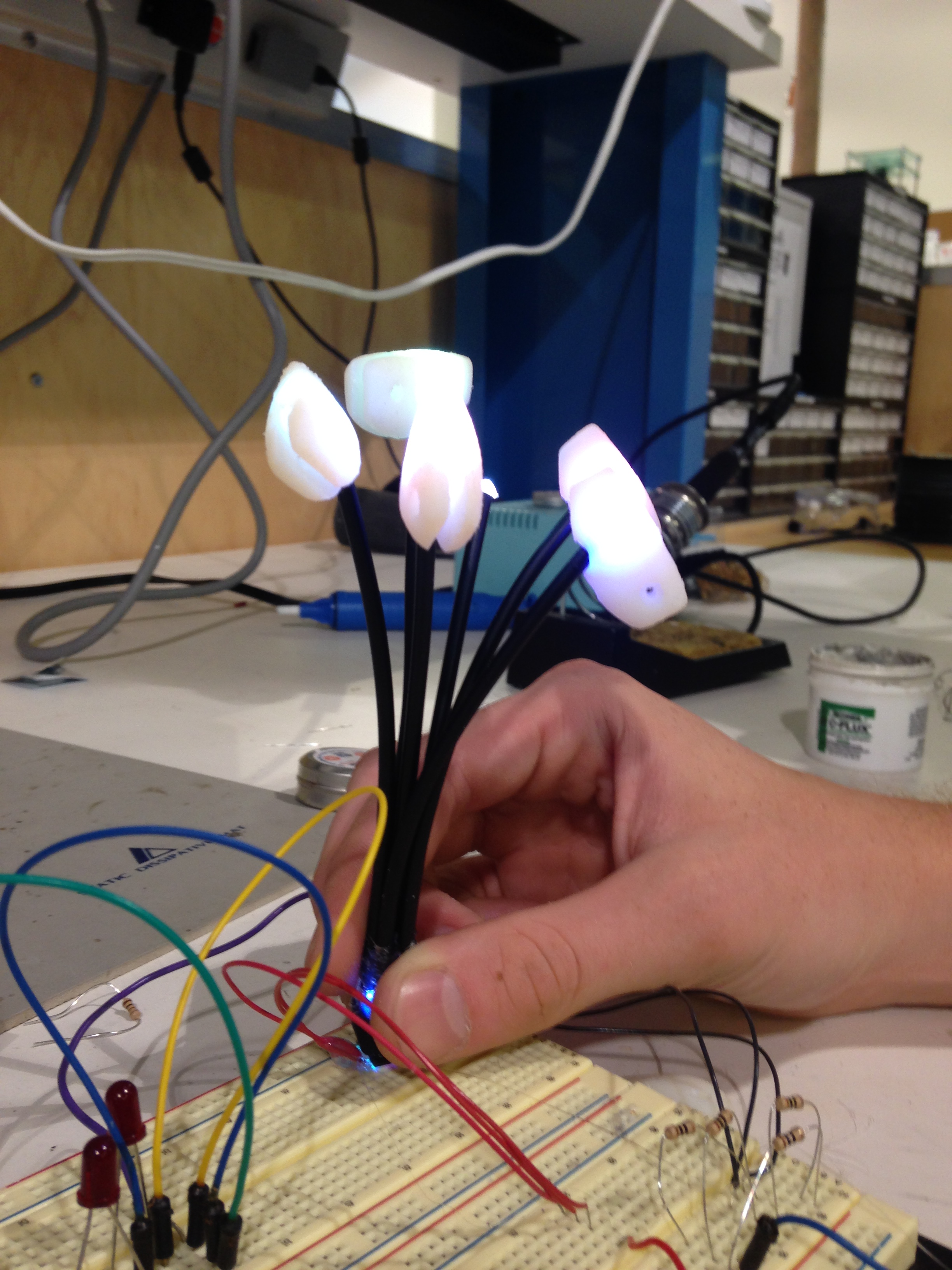

With the second version we knew we needed to re build it from the ground up so it could be easily attached to any bike. We moved from a self powered analog system to a battery powered digital prototype. We started building it using an Arduino Fio, because it had an on board battery connection, but we soon moved to the even smaller Arduino Mini.

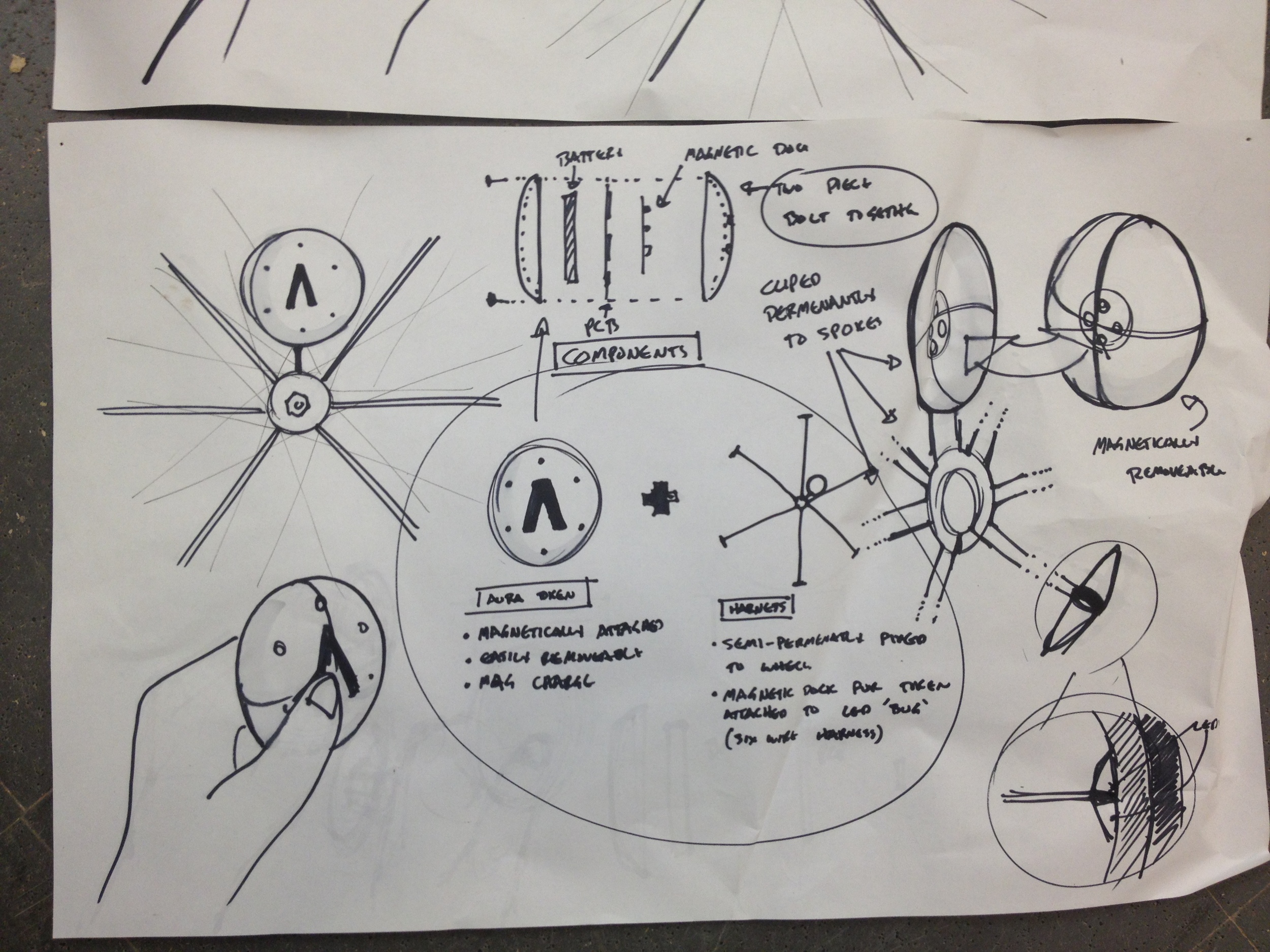

We started brainstorming around what the physical embodiment of the product would be. The size of the hardware was small, but not that small, and a moving bicycle wheel is not the most gentle or predictable environment. We did't really nail it down in this phase, but the exploration was the important part.

August 2012 - May 2013

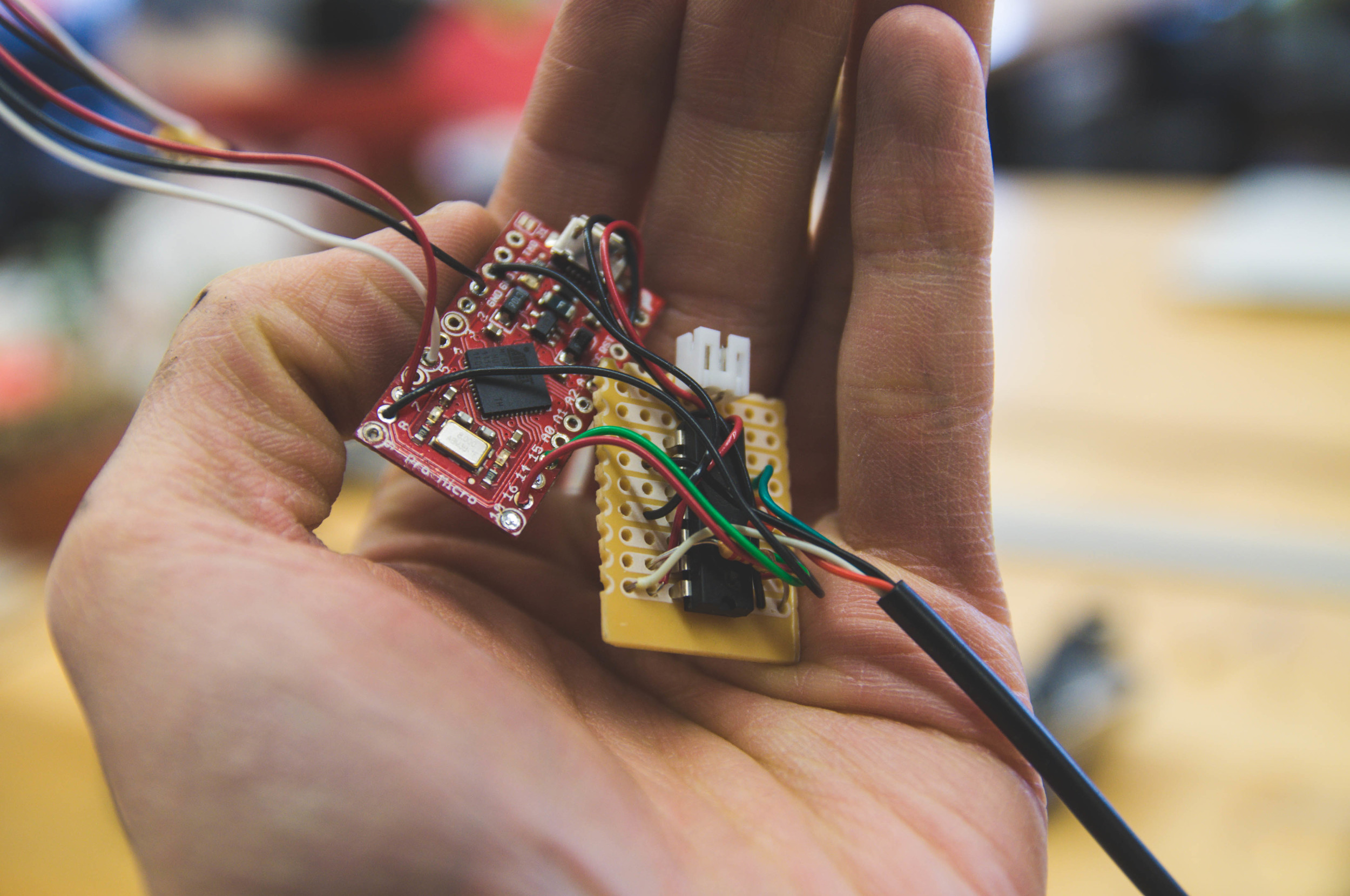

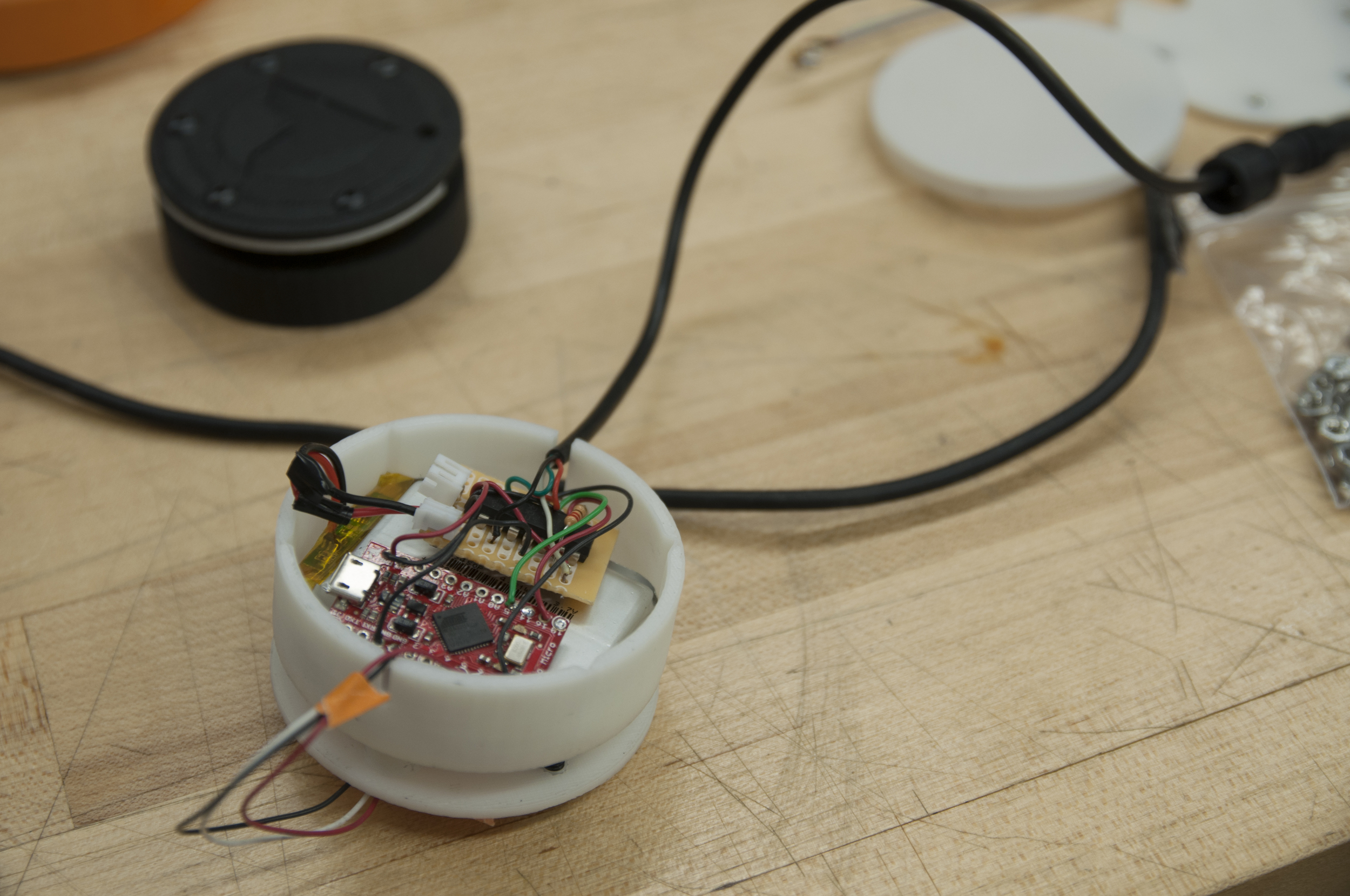

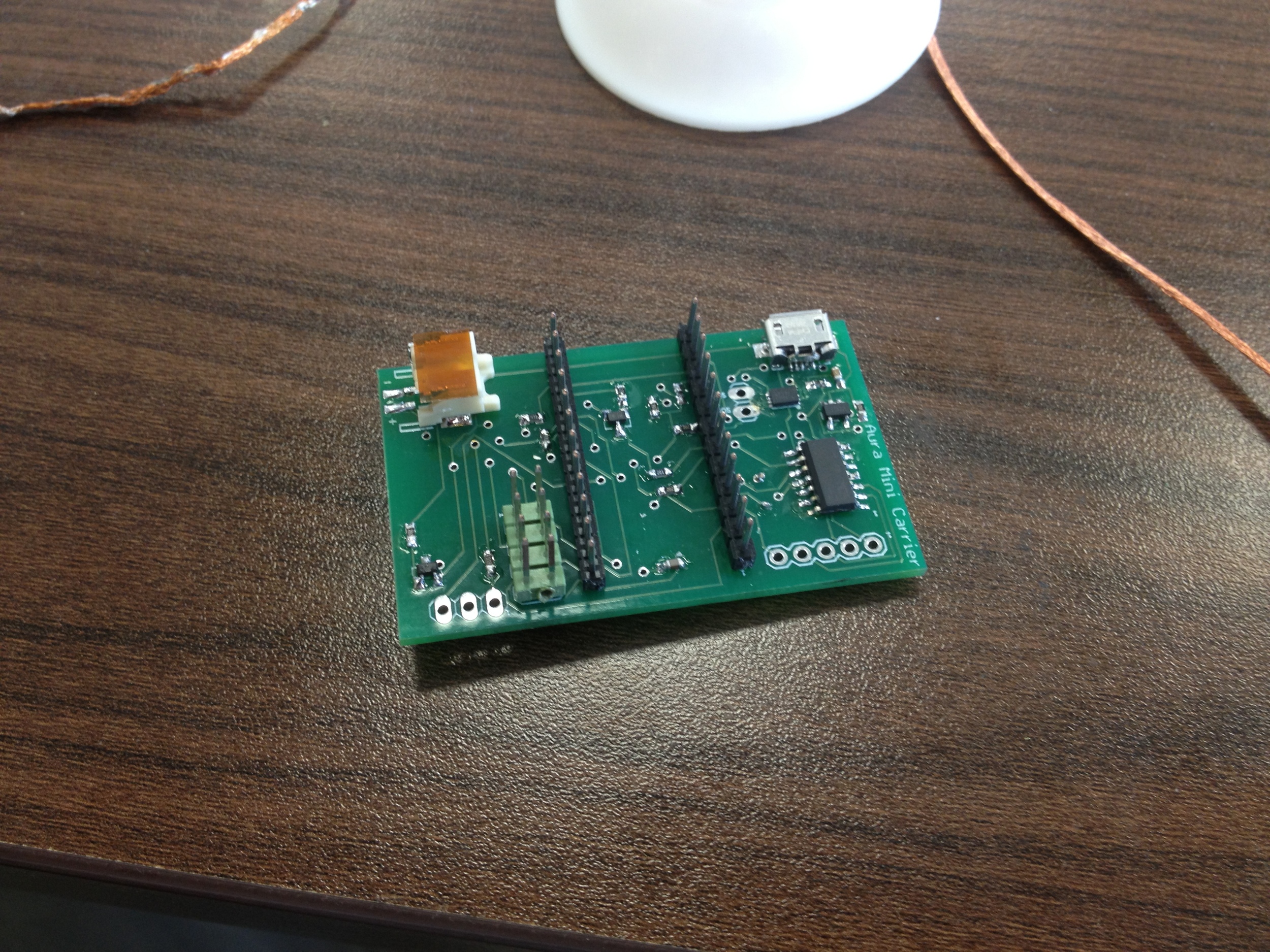

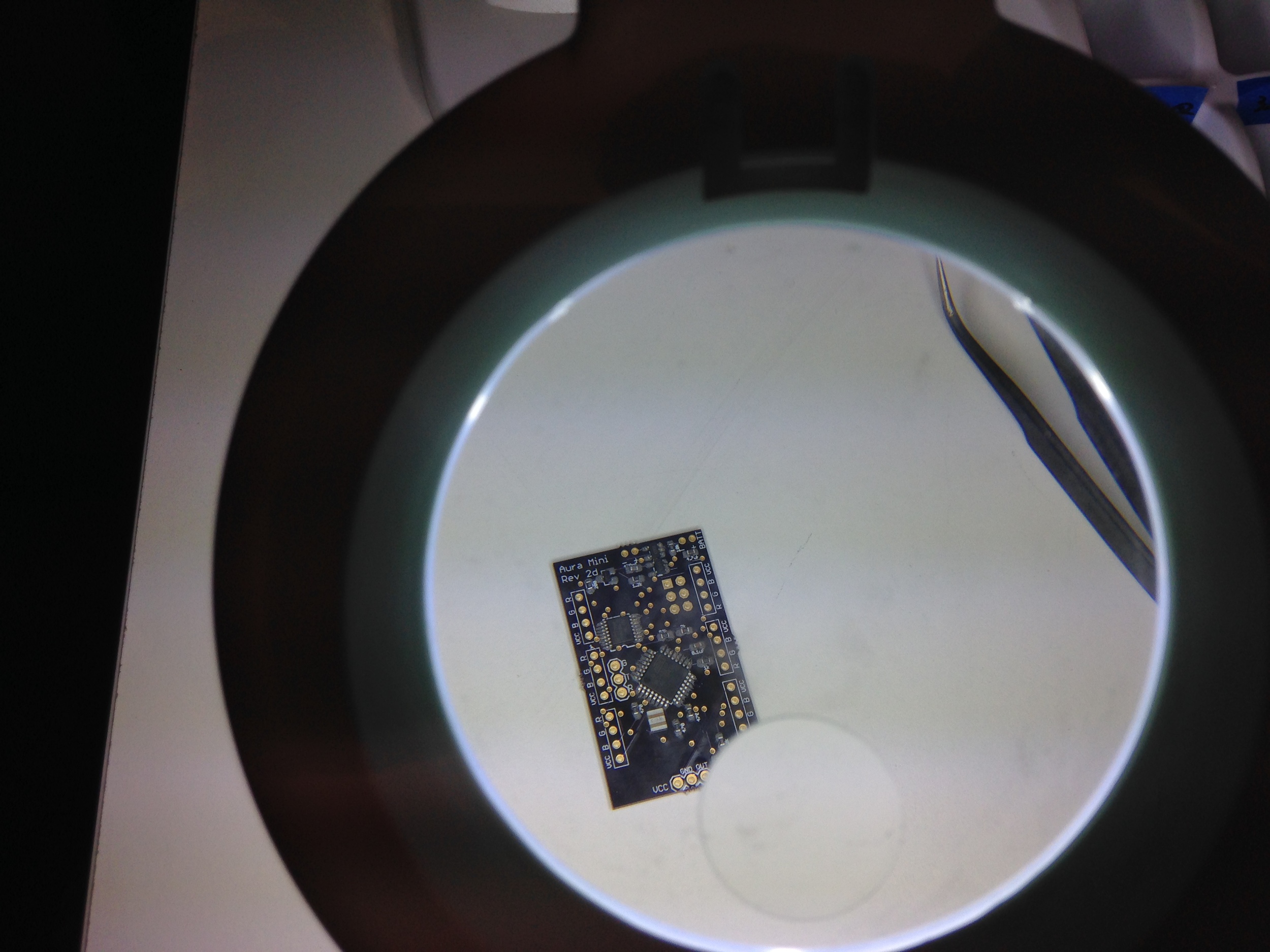

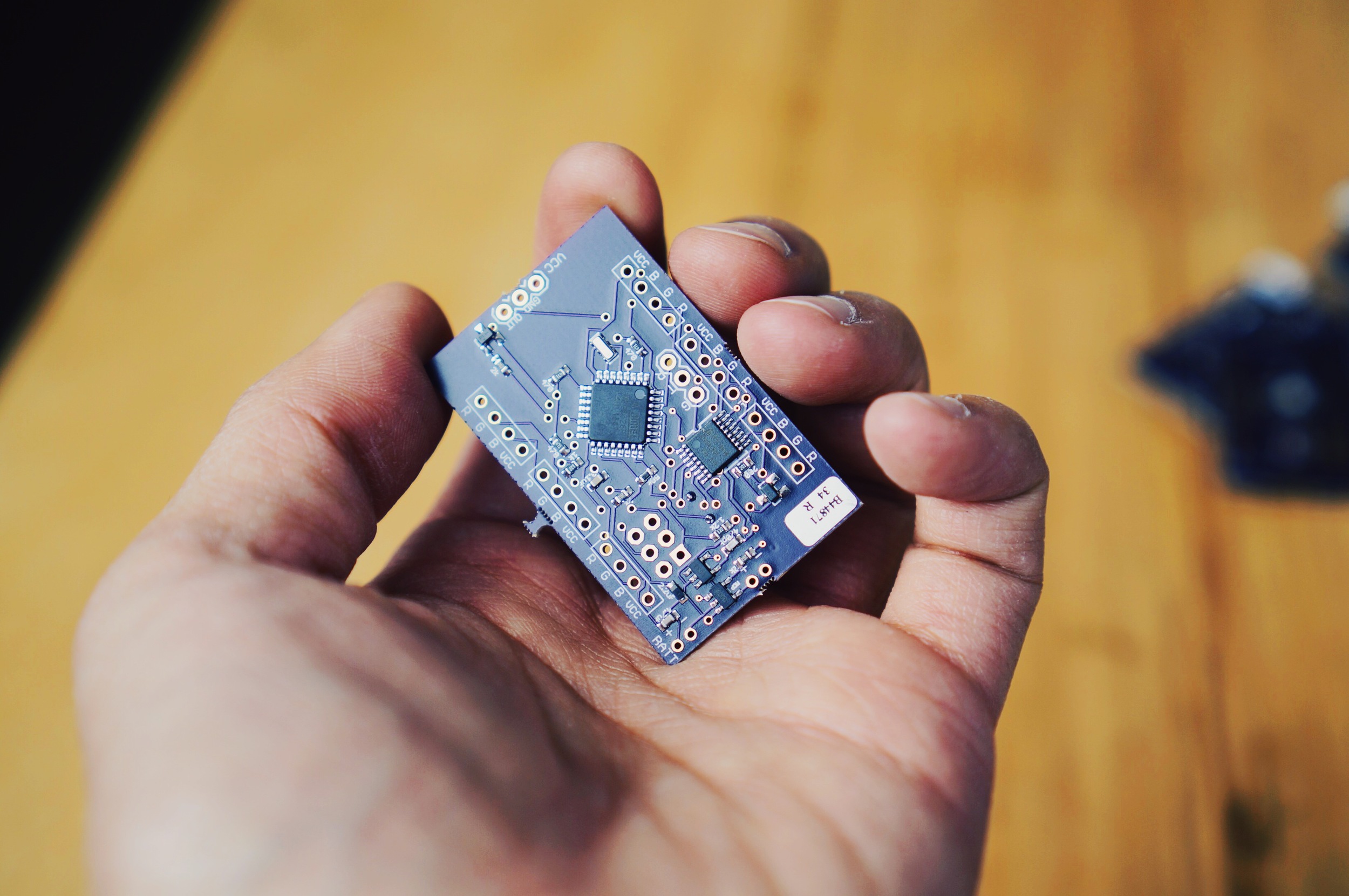

Piggybacking off the proven functionality of the initial Arduino prototype we set out to further refine the hardware. We brought on an engineer, Anshul, to help with the circuit boards and software. We started by making a carrier board for an Arduino mini. The carrier board was basically all new peripheral circuitry, drivers and battery components for the system, with an Arduino sitting on top of it acting as the brain. This allowed us to test our custom circuit, without having to worry about any errors on the controller side.

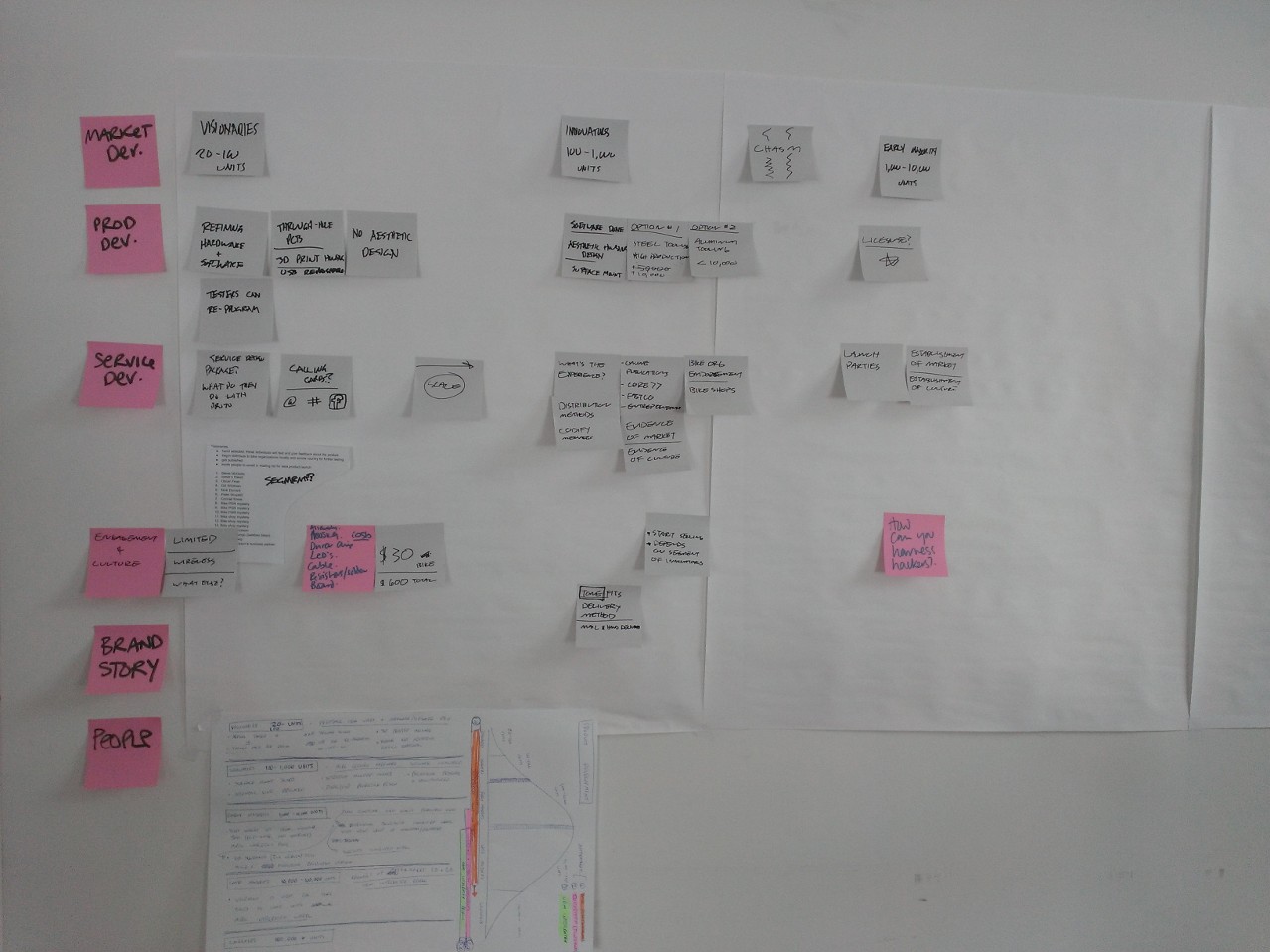

It was also during this time period that the we were starting to figure out the business side of the project. In September 2012 we were contacted by the largest bicycle manufacturer in the world, an Indian company. The chairman was in the US and came to Pittsburgh to meet with us and see the prototype in action. While that ended up falling through, it made us think of the potential scale. In December of 2012 we won $25,000 from the Business Bout competition, and accepted a place in the first class of a new accelerator in Pittsburgh called the Thrill Mill. We also won $15,000 from the Alva Fellowship in April 2013. This allowed us to truly move forward as a small business.

May 2013 - December 2013

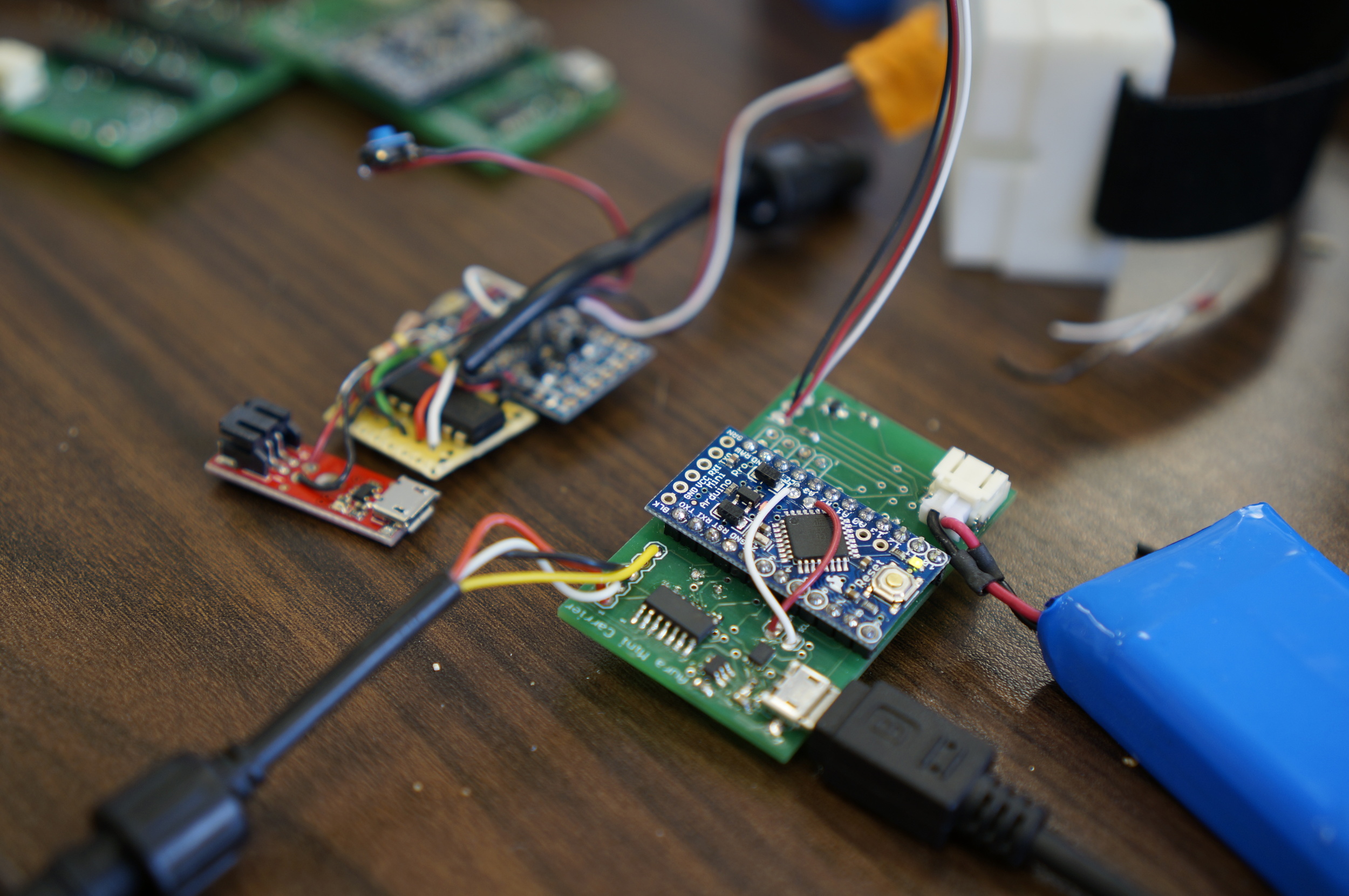

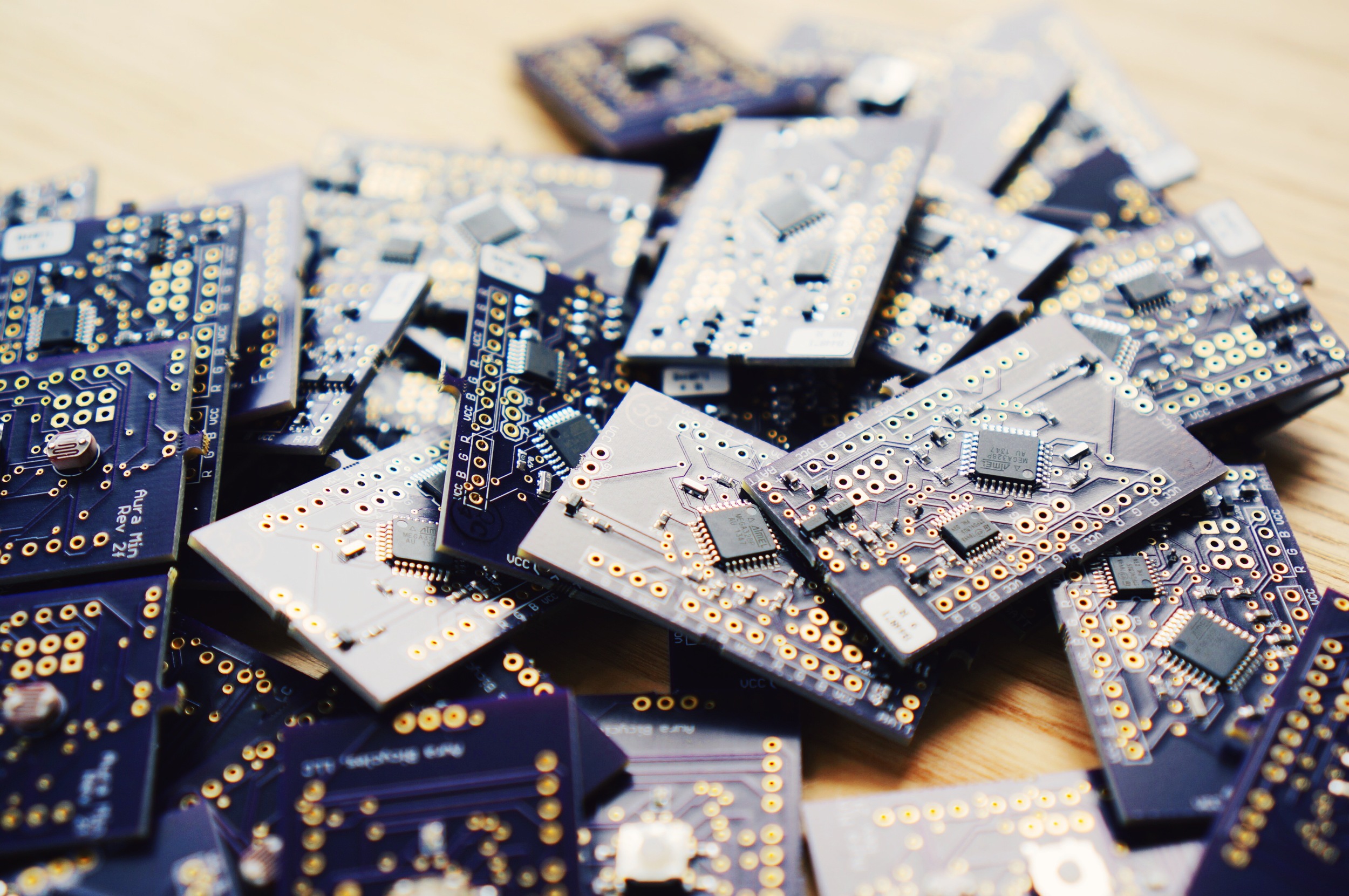

After graduating, Jonathan and I buckled down and started working on developing the product full time. We knew we still had a lot of usability issues to iron out and the circuit board and software still needed refinement too. We move completely away from the Arduino carrier board to a design that was 100% our own, with the help of another talented engineer, Steve Mcguire.

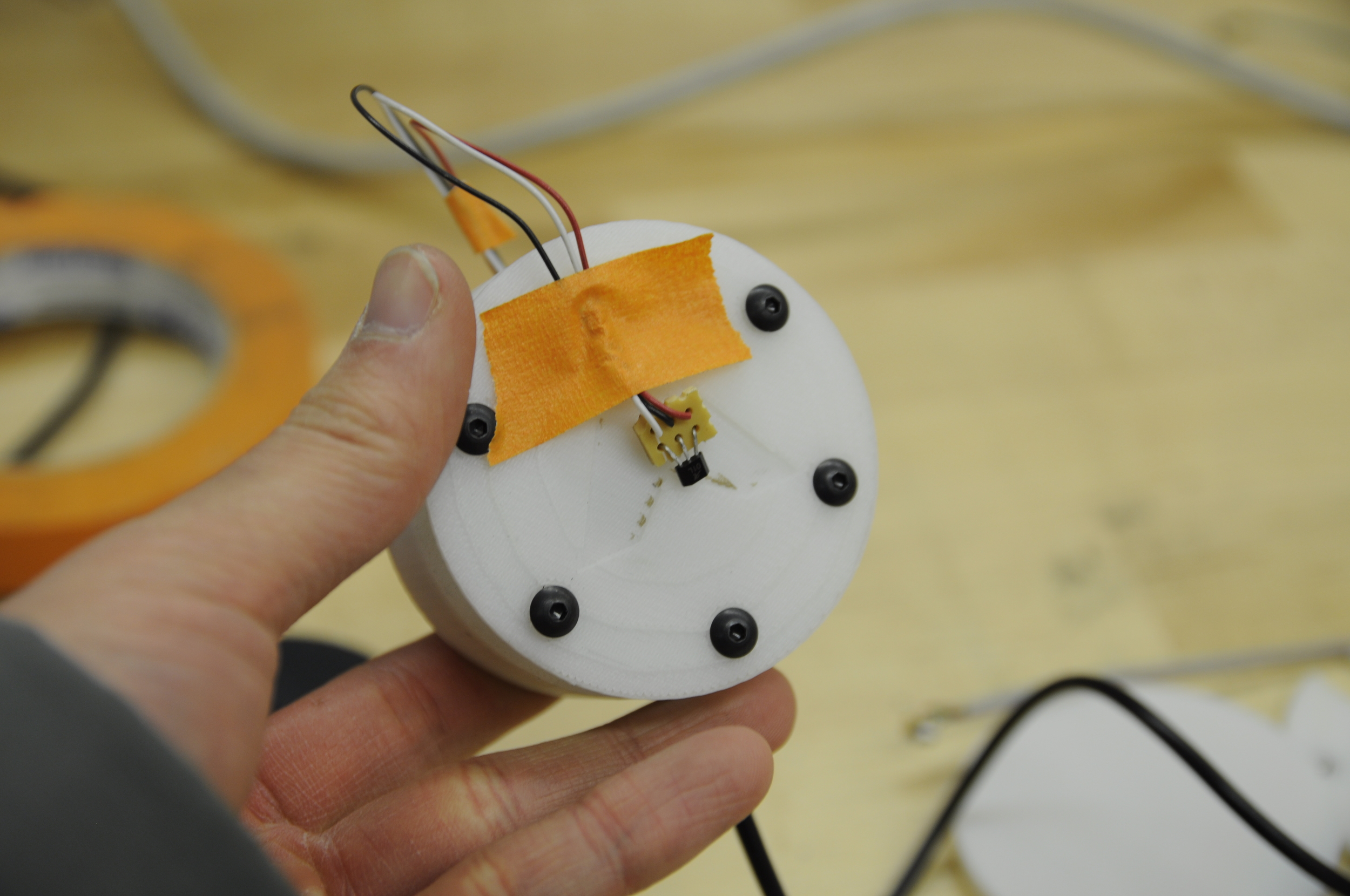

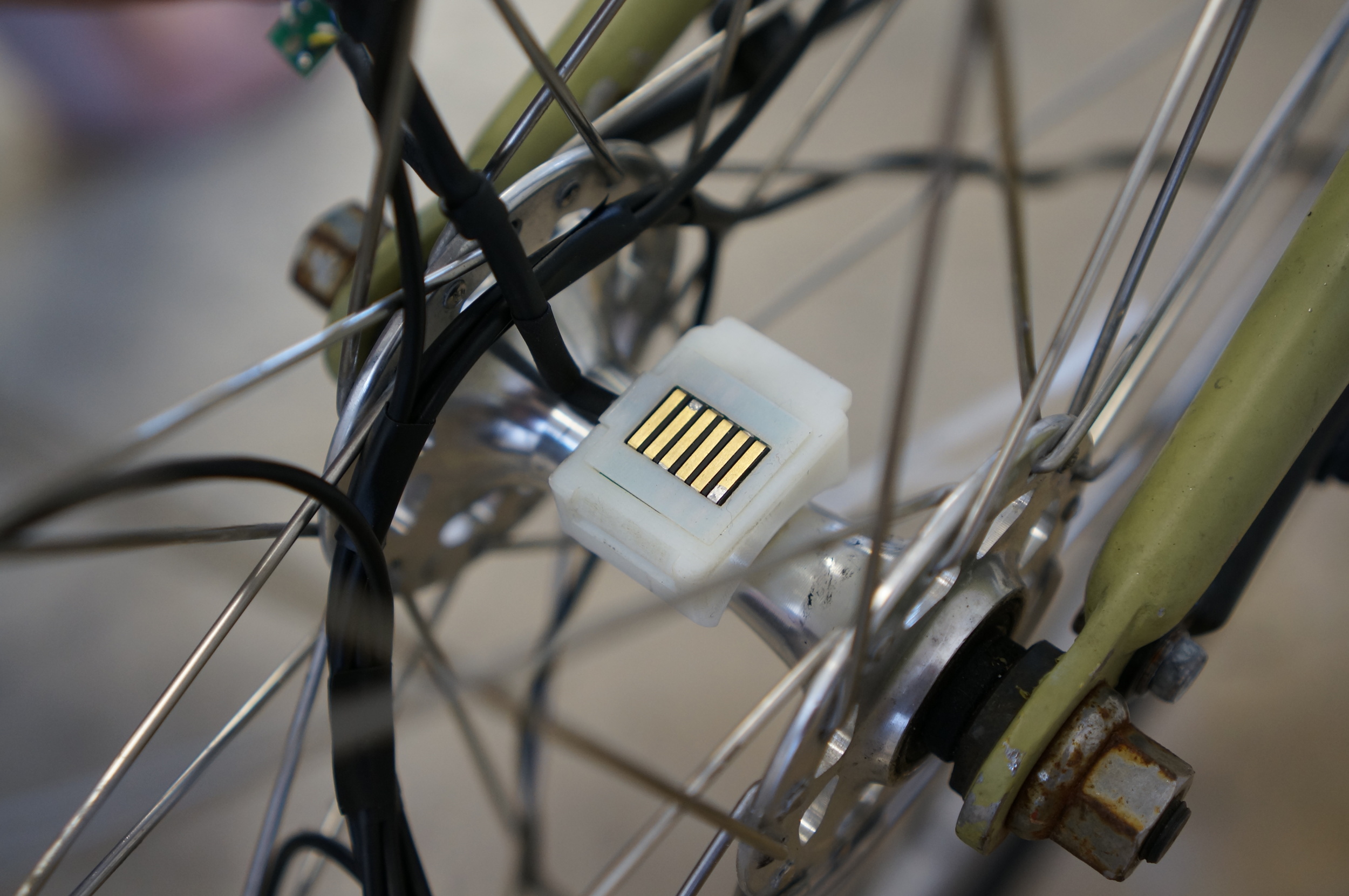

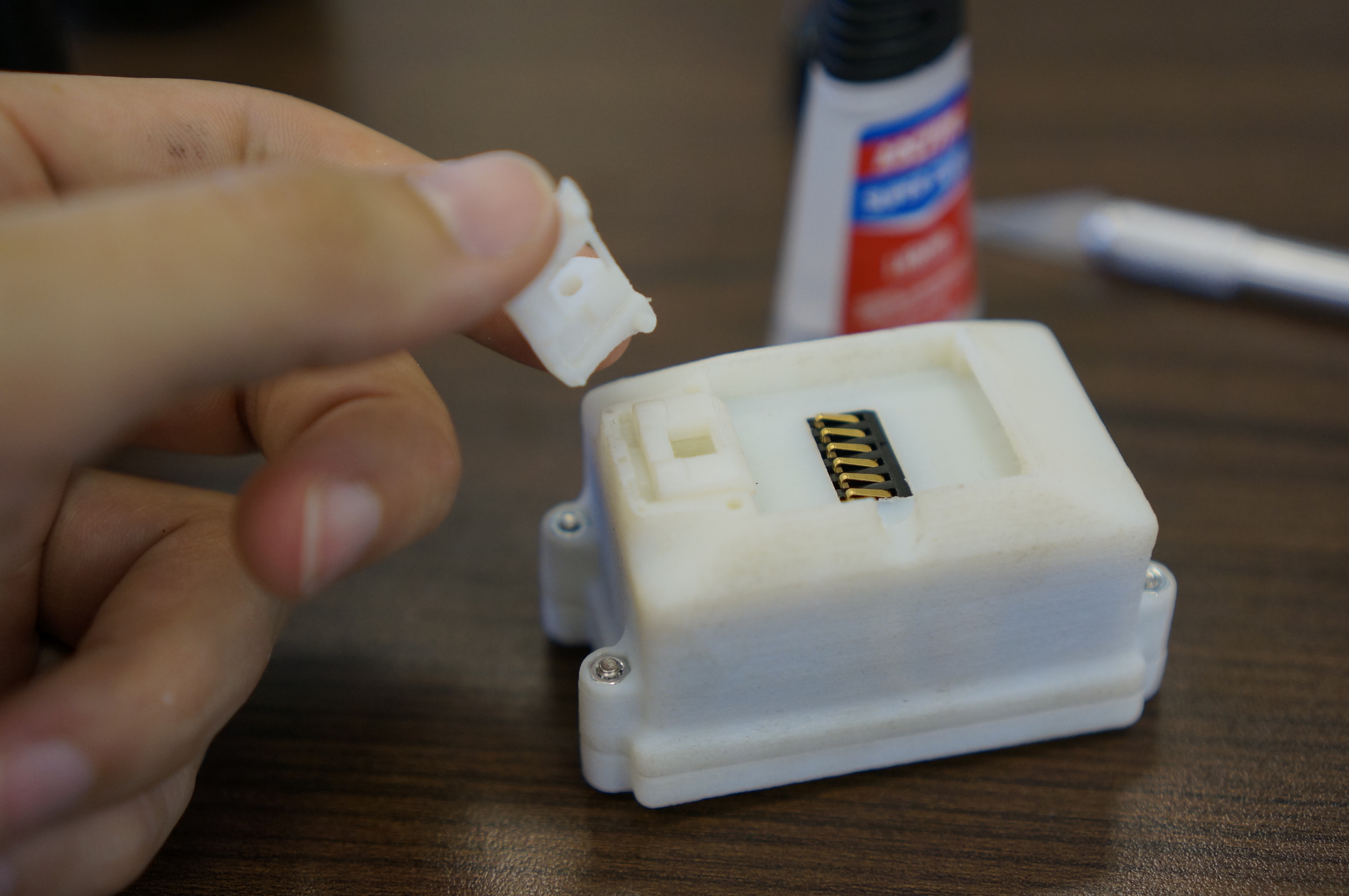

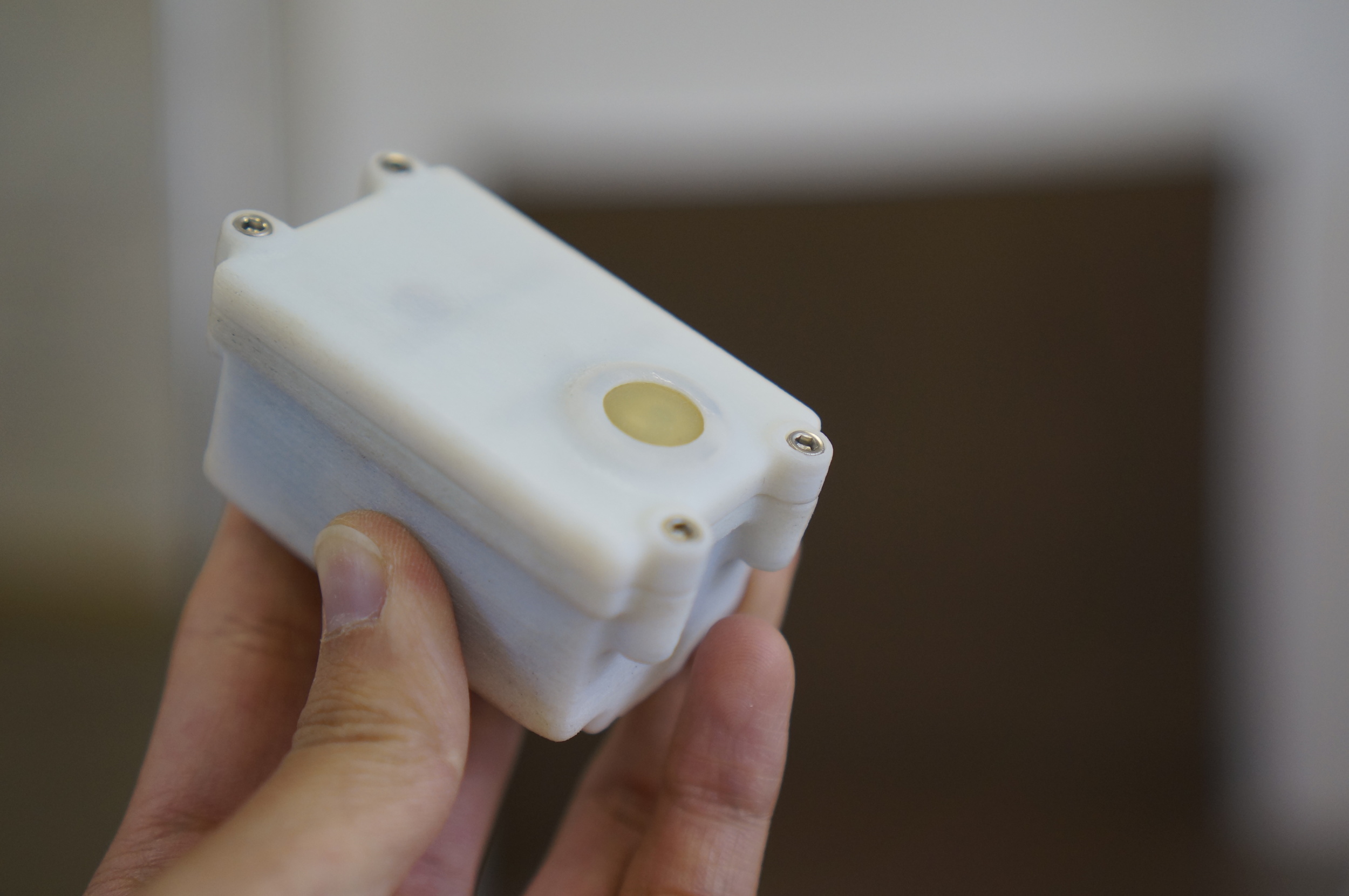

We also started playing with the housings, the manufacturability of the product, and all of the tangible user experience around it. The new version was two main parts, the LEDs on the wheel which were attached to a central hub mount, and what we called 'the brain' which was the main guts of the system - battery, circuit board and sensor package. The brain snapped on to the hub mount, which also provided an electrical/data connection to the LEDs on the wheel through small contacts. We manufactured 25 sets of lights to distribute to a group of riders doing beta tests for us. You can read more about that here.

We were working full time out of the incubator and trying at the same time to figure out the business side of the operation. That was always our biggest problem, we could sit and build prototypes all day, but neither of us could really own the business side of it. We decided the best plan of action would be to get it to a point where it was stable, and try to license the product to an existing bicycle accessory company.

We redefined our strategy around this new plan and started making connections in the industry. We flew out to Interbike in Las Vegas, the biggest industry show of the year. We had set up some meetings before hand, and were hoping to set up some more in person once there. We did meet some interested potential buyers, and the meeting we had set up before hand went really well. It was with a large sporting goods company based out of the west coast. In the end the talks did not pan out and we were getting closer to the red line in our bank account.

May 2014 - January 2015

We also made two huge steps forward with the technology. The first being moving from an external hall effect sensor that needed a magnet on the frame to read the speed of the wheel, to an internal gyroscope.

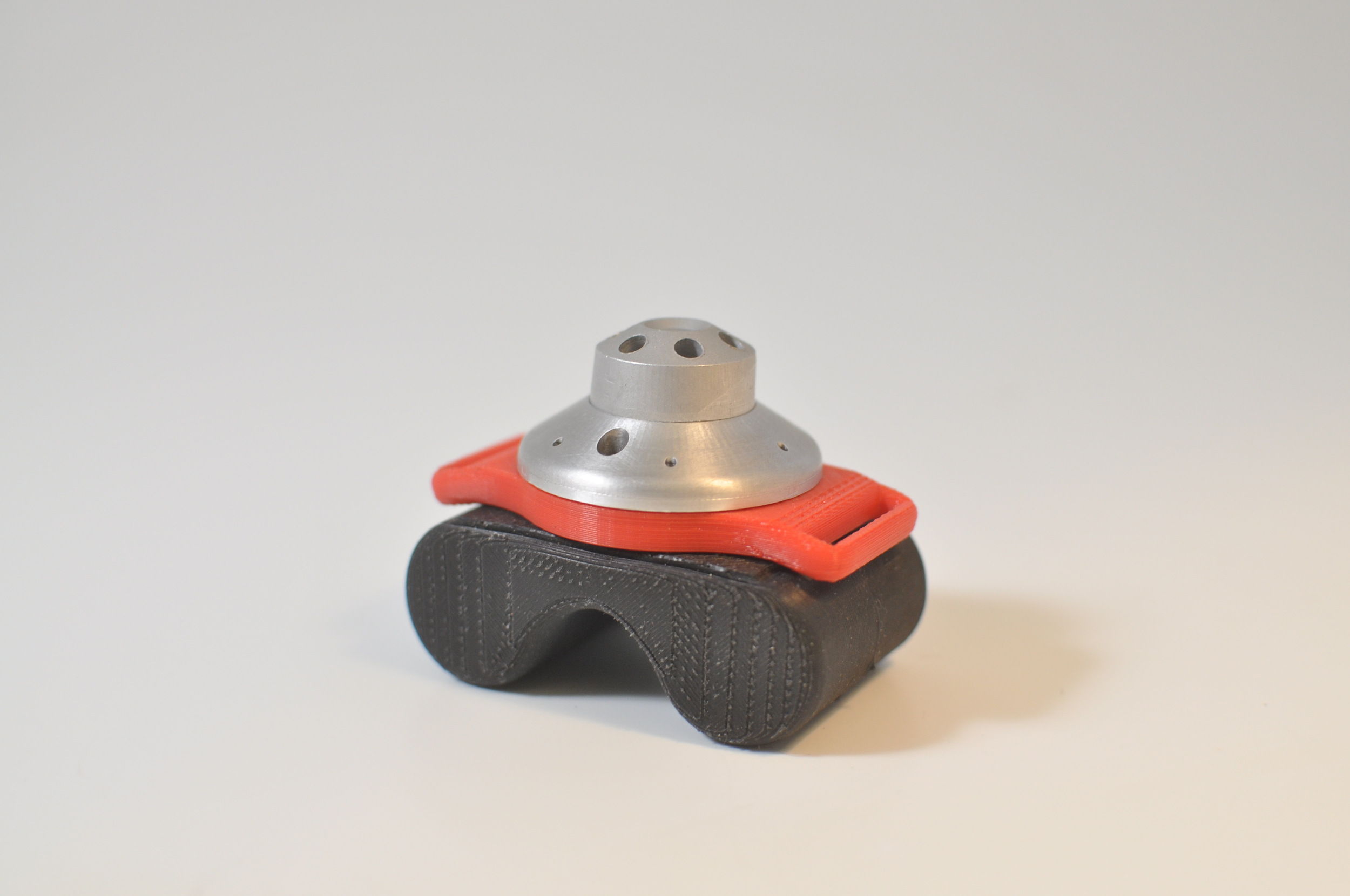

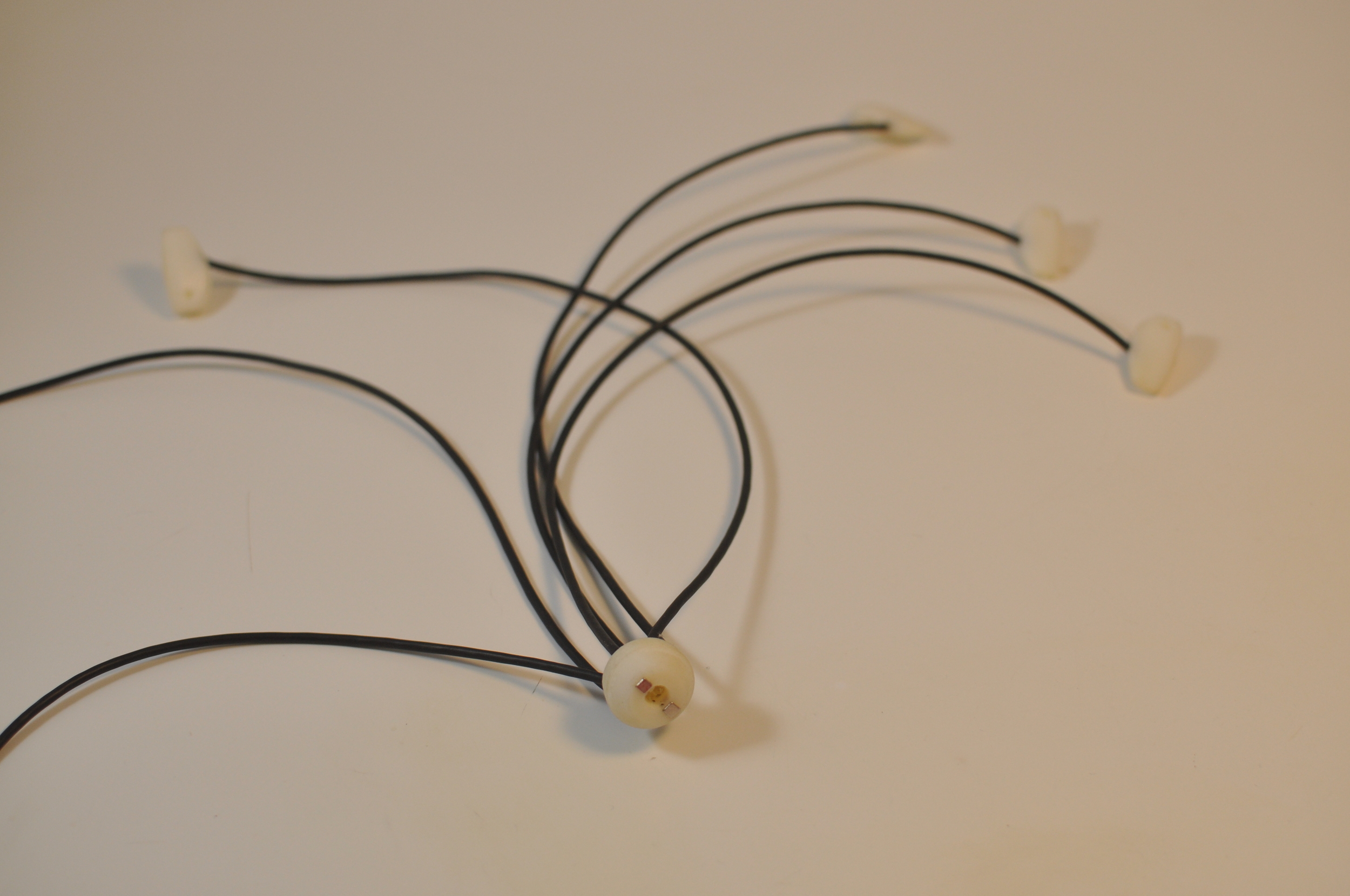

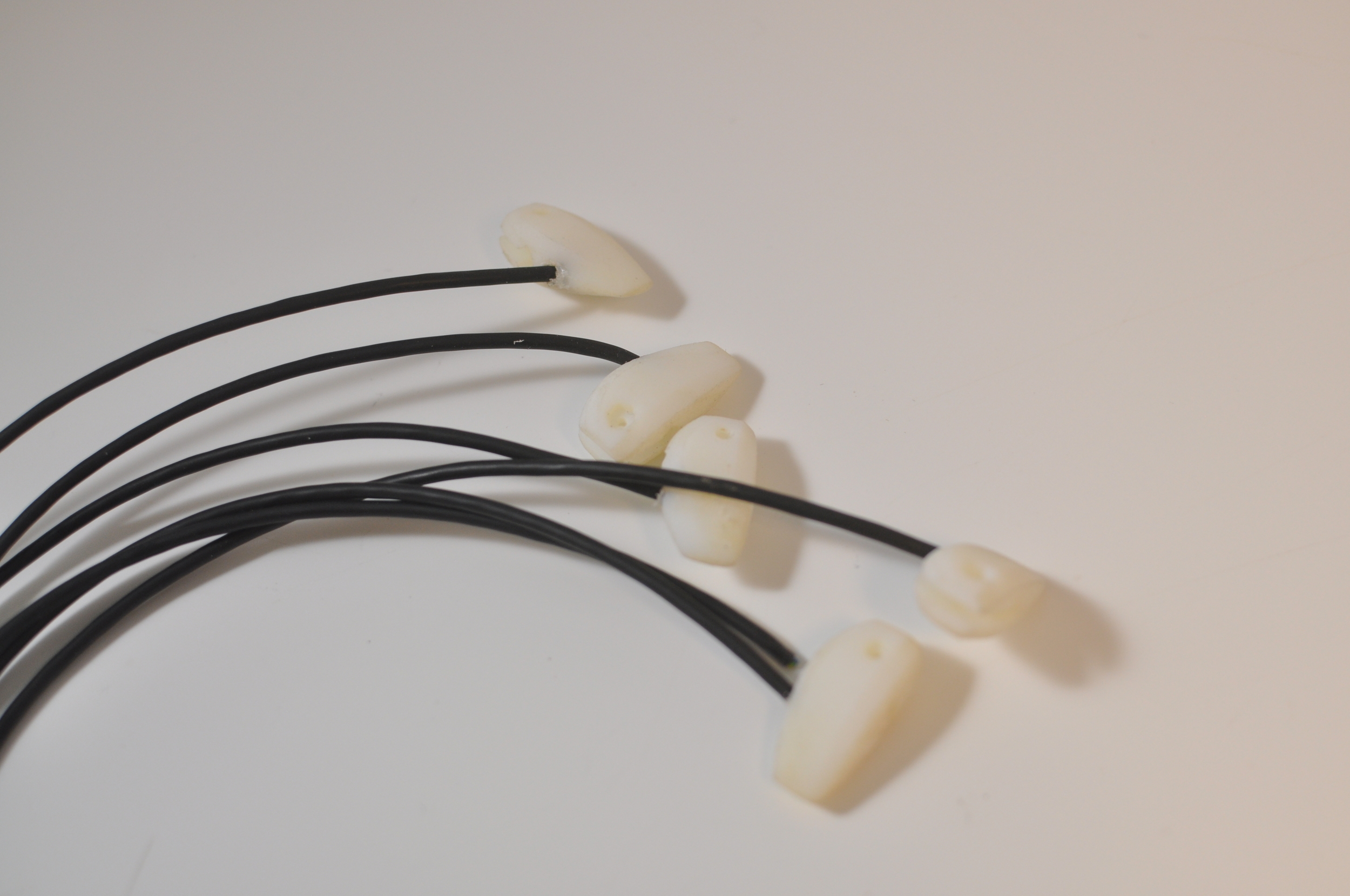

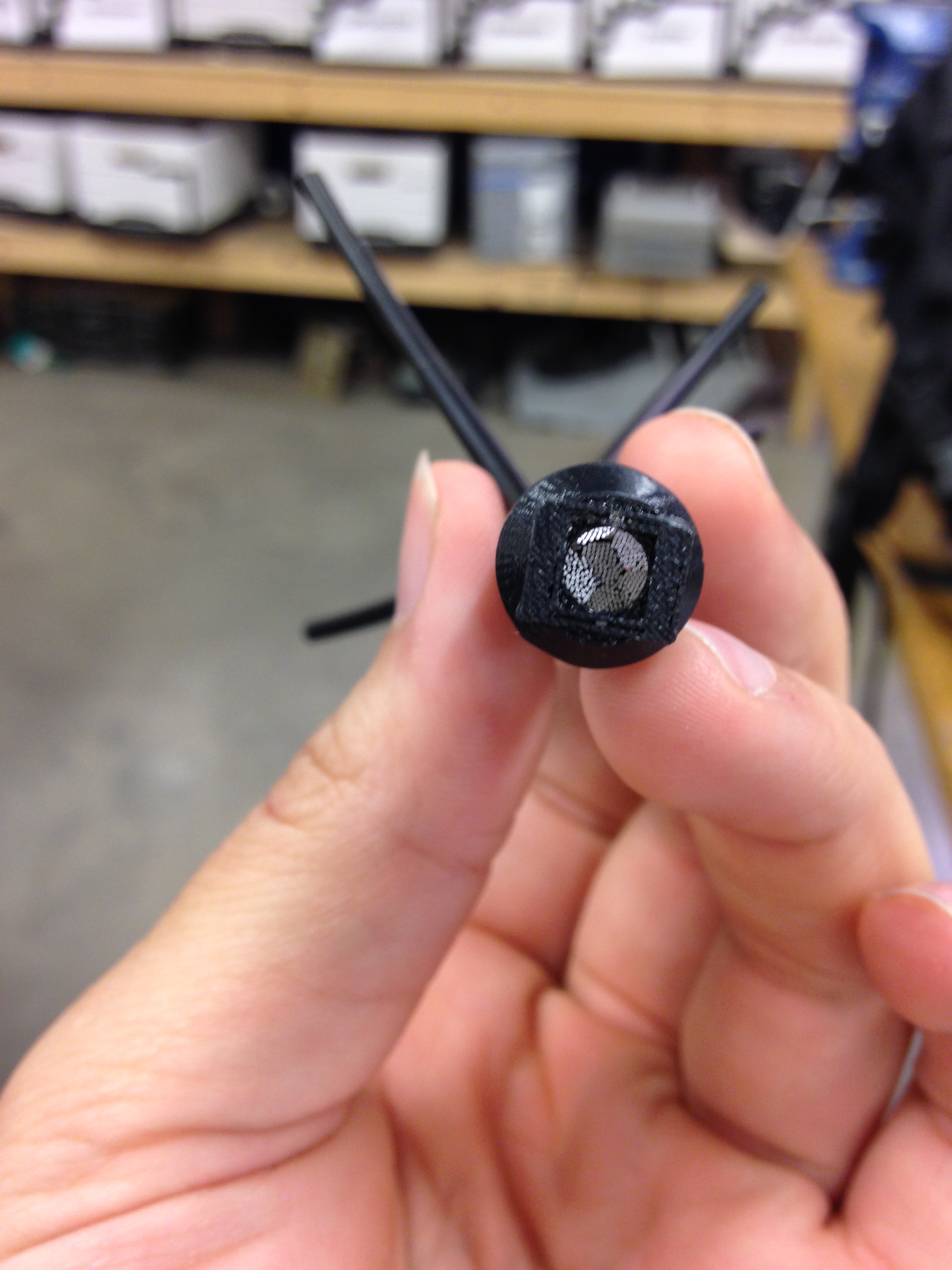

The biggest change we made however, was instead of an LED in each individual spoke clip, we put a single high powered LED in the center of the hub unit. The light was transmitted to the spokes via a fiber optic spider and an optical manifold to split the light into six equal streams. This was important because now we had 100% of the electronics on a single circuit board which we could seal, reducing complexity and manufacturing steps, while increasing the durability. The fiber optic nozzle attached to the hub unit with two magnets. When the nozzle is removed, these same magnets also provide a charging interface with a separate USB dongle

We decided to take a short break from the project. Jonathan got a job out west and I decided to give it one last go. I brought on an awesome mechanical engineer Matt and an additional intern for the summer Bruno. The internals and the code were already pretty stable. I really wanted to re-think the industrial design and user experience from the ground up.

The new version of the product was a total redesign compared to previous versions. It consisted of a hub unit and a removable spider which connected the hub to the spoke clips. The hub unit has a soft silicone base which houses two cylindrical batteries and sits straddling the hub. This brings the weight as close to the center axis of the hub as possible. The upper part houses the circuit board and is made from machined aluminum. The whole unit is strapped to the hub with velcro.